Modern transformer oil dielectric testers have evolved significantly due to technological advancements, making them superior in performance and reliability. Some key advancements include:

- Automated Testing: Modern testers often feature automated processes, reducing human error and ensuring consistent and accurate test results. Automated functions streamline testing procedures, making them more efficient.

- Advanced Measurement Techniques: Improved measurement techniques enhance accuracy and sensitivity. Testers now use sophisticated algorithms and sensors to detect even minor changes in dielectric strength, providing more precise readings.

- Faster Testing: Technological advancements have led to quicker test times without compromising accuracy. Speedier testing allows for more efficient maintenance procedures and reduces downtime for transformers.

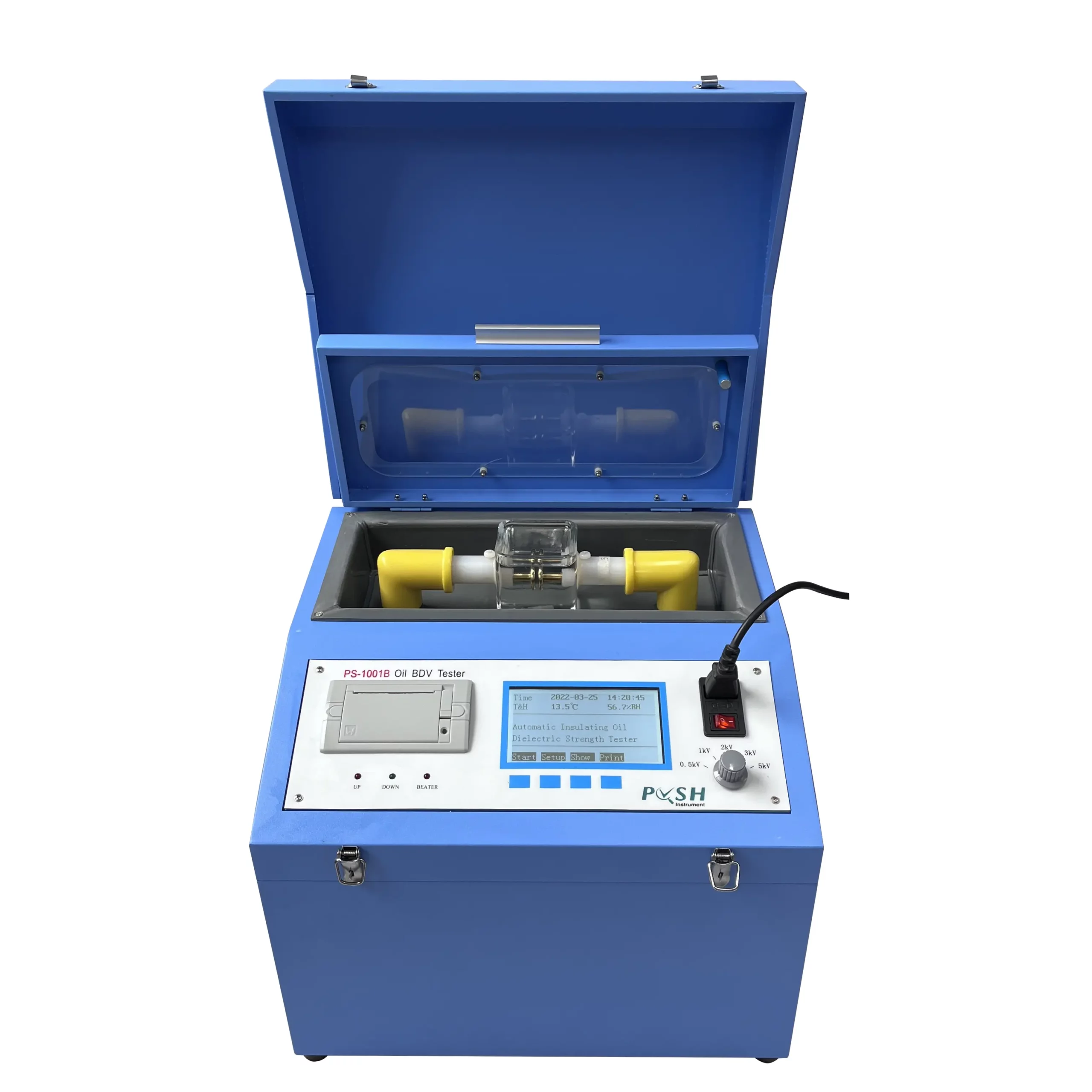

- Portability and Compact Design: Many modern testers are more portable and compact, allowing for ease of transportation and use in different locations or within confined spaces. This enhances their versatility and accessibility.

- Integration with Digital Systems: Integration with digital systems enables easier data management and analysis. Testers can connect to software platforms for storing, analyzing, and sharing test results, facilitating better decision-making and trend analysis.

- Remote Monitoring Capabilities: Some advanced testers offer remote monitoring features, allowing operators to conduct tests and access results from a distance. This capability is particularly beneficial for remote or inaccessible locations.

- Improved User Interface: Intuitive interfaces and user-friendly designs make modern testers more accessible to operators with varying levels of expertise. Clear displays and simplified controls enhance usability.

- Comprehensive Diagnostic Capabilities: Modern testers may incorporate multiple diagnostic tests beyond BDV, allowing for a more comprehensive assessment of transformer oil quality. This includes tests for moisture content, acidity, and more.

- Enhanced Safety Features: Advanced testers often include safety features to protect both the equipment and operators. These features may include overload protection, insulation monitoring, and safety interlocks.

- Calibration and Self-Diagnostics: Self-diagnostic capabilities and built-in calibration features ensure the accuracy and reliability of the tester. These functionalities help maintain the instrument’s performance over time.

- Compatibility and Connectivity: Modern testers may offer compatibility with various oil types and transformer models. Additionally, they often have connectivity options such as USB, Bluetooth, or Wi-Fi for seamless data transfer.

These technological advancements collectively contribute to the superior performance, accuracy, reliability, usability, and efficiency of modern transformer oil dielectric testers, empowering maintenance personnel with more effective tools for assessing transformer health and ensuring operational reliability.

How does the portability of an transformer oil dielectric tester impact its usability in various maintenance scenarios?

The portability of a transformer oil dielectric tester significantly enhances its usability in various maintenance scenarios due to several reasons:

- Accessibility to Remote Locations: Portable testers can be easily transported to remote or hard-to-reach locations where transformers are installed. This accessibility ensures that maintenance and testing can be conducted regardless of the transformer’s location.

- On-site Testing Capability: Portability allows for on-site testing without the need to transport oil samples to a laboratory, saving time and resources. This immediate on-site testing capability facilitates quick assessments and decisions.

- Versatility in Maintenance Practices: In scenarios where multiple transformers are spread across a facility or in different locations, a portable tester offers the flexibility to test various transformers without the need for multiple fixed testing setups.

- Reduced Downtime: Portability minimizes downtime by enabling swift testing procedures. Maintenance personnel can quickly move from one transformer to another, transformer oil dielectric tester conducting tests efficiently and reducing the time the equipment remains offline.

- Field Maintenance and Emergency Situations: During field maintenance or emergency situations, portable testers are indispensable. They allow for immediate assessments of transformer oil quality, aiding in rapid decision-making and prompt actions.

- Ease of Handling: Portable testers are designed to be lightweight and easy to handle. This ease of handling facilitates quick setup and operation, making them suitable for use by maintenance technicians in various scenarios.

- Cost-Effective Testing: Portable testers eliminate the need for frequent transportation of oil samples to laboratories, reducing transportation costs. Additionally, they lower the reliance on external testing services, saving on outsourcing expenses.

- Real-time Data: On-site testing with a portable device provides real-time data, allowing maintenance personnel to make immediate decisions based on the test results without delays caused by waiting for laboratory reports.

- Field Calibration and Validation: Some portable testers offer field calibration and validation features, ensuring accuracy and reliability without the need to send the device to a specialized calibration facility.

In summary, the portability of a transformer oil dielectric tester enhances its usability by offering accessibility, versatility, reduced downtime, cost-effectiveness, ease of handling, real-time data, and the ability to perform on-site testing in various maintenance scenarios, ultimately contributing to efficient and timely maintenance practices.