HOW DO RIGID COUPLINGS AND FLEXIBLE COUPLINGS DIFFER?

Ultimately, the key difference between rigid and flexible couplings is in the connection they provide. Rigid couplings provide a rigid connection; the two shafts are firmly connected, and the coupling allows for a smooth transmission of torque throughout the system. Flexible couplings create flexible connections, and the components can lose some of the torque power through the interaction. While metallic flexible couplings offer greater torque capability than other flexible couplings, some torque is still lost.

Other important differences between rigid and flexible couplings are:

- Alignment Requirements: Flexible couplings can handle slightly misaligned shafts. Rigid couplings are torsionally stiff and can’t tolerate any misalignment. This applies to both shafts that are physically misaligned at rest and parts that may cause misalignment during operation due to thermal changes.

- Backlash: Rigid couplings, especially newer models of aluminum rigid couplings, can significantly reduce backlash to at-zero or near-zero levels. Flexible couplings don’t offer the same protection.

- Maintenance Requirements: Because rigid couplings are stiff, they do not absorb vibrations, which can lead to early wear on parts that aren’t properly aligned. Operators should routinely check rigid couplings for wear and alignment, and they should also routinely apply lubricant. Flexible couplings can handle vibration and shock without adverse wear.

- Complexity: Flexible couplings often have more components and/or are more complex. This can make operation and maintenance more complicated. Rigid couplings are more simple and straightforward in comparison.

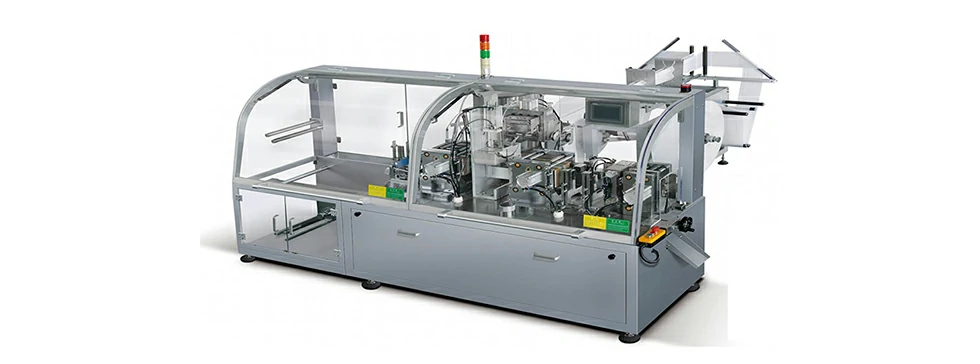

- Applications: Flexible couplings can be used in servos with low or moderate torque levels and the potential for shaft misalignment. This includes applications such as machining tools, semiconductor manufacturing, and packaging equipment. Rigid couplings work best for high-torque requirements, shaft support applications, and push-pull use cases.

- Cost: Rigid couplings are more affordable than flexible couplings, which tend to have a high cost.

ADVANTAGES OF RIGID COUPLINGS

Both rigid and flexible couplings have their place in almost any complex motion system. However, rigid couplings provide several advantages over their flexible alternatives that make them the preferred choice for many projects. Some of their key advantages include:

- Excellent torque transmission: Rigid couplings can efficiently transfer torque from one shaft to the other connected shaft.

- Low cost of production: Manufacturers can produce standard and custom rigid couplings at cost-effective rates.

- Precision, with nearly zero windup and zero backlash

- Torsional stiffness: High torsional stiffness allows for better positioning.

- Simplicity

- Alignment capabilities: Rigid couplings can be used to establish shaft alignment between the motor and connected components.

- Suitability for push-pull and support applications

- Easy assembly, disassembly, and maintenance operations throughout the life of the coupling

HIGH-QUALITY RIGID COUPLINGS FROM STAFFORD MANUFACTURING

Rigid couplings provide excellent torque, minimal backlash (with some of our standard couplings providing zero backlash), and high torsional stiffness. This makes them ideal for a wide variety of precision applications that need high levels of power. At Stafford Manufacturing, we manufacture and supply our clients with high-quality rigid couplings for a range of applications. Learn more about how to choose the right rigid coupling for your needs, or browse our catalog to find the right products today.

.jpg?x-oss-process=style/app)