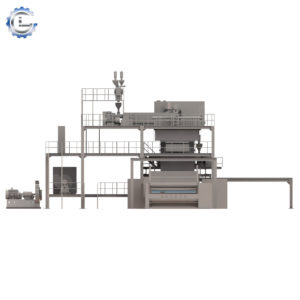

China is one of the largest manufacturers of PP (polypropylene) SSS (spunbond, spunbond, spunbond) non-woven fabric production lines in the world. These machines are used to produce non-woven fabrics for various applications such as hygiene products, medical supplies, agricultural covers, and geotextiles.

The materials used in the construction of these machines play an important role in determining their quality, durability, and efficiency.

Here are some of the materials commonly used in China’s PP SSS spunbond machines:

Steel: The machine frame and other critical parts are made of high-quality steel to ensure stability and precision during operation.

Motors: High-performance motors are used to drive the various components of the machine, such as the extruder, spinneret, and winding system.

Heating elements: Advanced heating elements, such as ceramic heaters, are used to heat the polymer material to the correct temperature for extrusion.

Filters: The spunbond process requires the use of filters to remove impurities from the polymer material. China PP SSS Spunbond Machine China’s PP SSS spunbond machines use high-quality filters to ensure consistent product quality.

Belts: Conveyor belts are used to transport the non-woven fabric through the production process. These belts are made of durable materials such as polyester to ensure long-lasting performance.

Electronics: China’s PP SSS spunbond machines are equipped with advanced electronic controls to monitor and adjust various aspects of the production process, such as temperature, pressure, and speed.

Spare parts: Manufacturers of PP SSS spunbond machines in China often provide spare parts made of high-quality materials to ensure long-term performance and reduce downtime for maintenance and repairs.

In summary, China’s PP SSS spunbond machines are constructed using high-quality materials to ensure consistent, high-quality production of non-woven fabrics for a variety of applications.

China PP SSS Spunbond Machine History

The history of PP SSS spunbond machine development in China dates back to the 1990s. Prior to this, China relied heavily on imported non-woven fabrics for various applications. In the early 1990s, several Chinese companies began developing their own non-woven fabric production lines using PP (polypropylene) as the raw material.

The first generation of PP spunbond machines in China were mainly based on technology imported from Europe and the United States. These machines were mainly used to produce single-layer non-woven fabrics for disposable products such as diapers and sanitary napkins.

In the late 1990s and early 2000s, Chinese manufacturers began to develop their own technology and improve the performance of their machines. This led to the development of multi-layer spunbond machines, which could produce non-woven fabrics with improved strength, softness, and other properties.

By the mid-2000s, China had become a major manufacturer of non-woven fabrics, with a large number of companies producing PP SSS spunbond machines. The rapid growth of the non-woven fabric industry in China was driven by increasing demand from both domestic and international markets.

In recent years, Chinese manufacturers have continued to improve the performance and efficiency of their PP SSS spunbond machines, and have also developed new applications for non-woven fabrics in industries such as construction, agriculture, and automotive. Today, China is one of the world’s largest producers of non-woven fabrics, with a strong presence in both domestic and international markets.